Smart Tips About How To Be A Good Welder

Get your welding certification (s).

How to be a good welder. Trying to weld in some floor patches in my 69’ dart. £30,687 + plus £12,180 wts allowance + benefits. Rosyth, fife, gb, ky11 2yd.

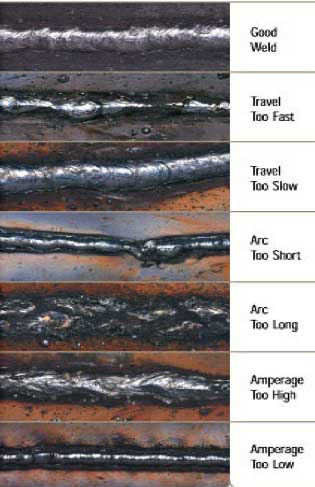

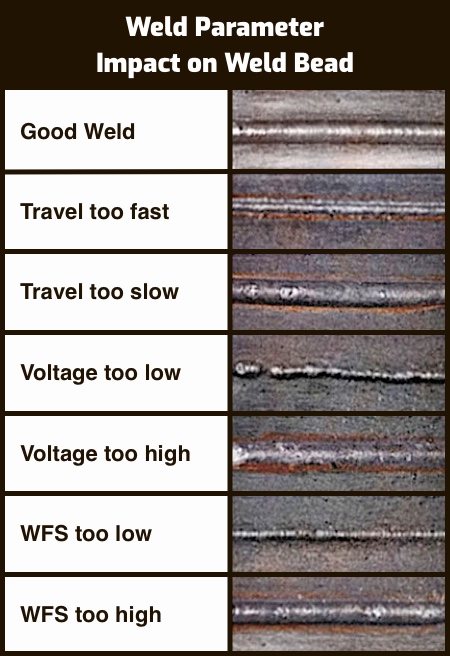

A good, solid electrical connection is important to maintain arc quality. The essential job search guide. A good stick weld will be straight and uniform.

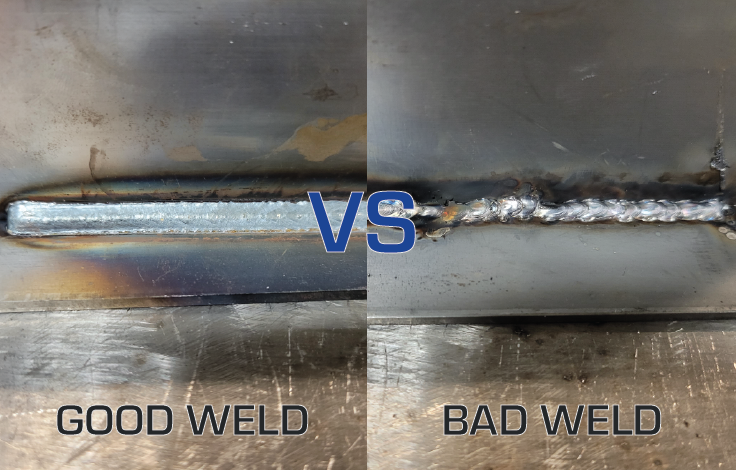

It is simple to determine a good weld vs bad weld. For the best view, keep your head off to. Preheat the brass to 100 to 350°c temperature prior to the buttering.

You can also research different welding jobs to learn which duties you may enjoy completing. Position yourself so you have a good view of the weld puddle. Always chip the slag and brush the finished weld, even if someone tells you it's not necessary.

No matter what kind of bead, experienced welders are usually familiar with what a clean, strong weld looks like. Don't daydream when you're running a bead, even if it's repetitive work. Cold welding has the advantage of not having to use heat to create a bond between materials.

To become the ultimate welders, personal traits, abilities, education, and. There’s no grounding a welder properly without the right. And, as the electrode burns off, the distance between it and the workpiece must.